7 Effective Ways to Improve Plant Maintenance and Prevent Costly Repairs

As a plant manager, you know that keeping your operations running smoothly and efficiently is essential to producing the best products or services. But how do you ensure that your maintenance program is effective? In this article, we’ll explore seven effective ways to improve plant maintenance and prevent costly repairs. Read on to learn more about how you can keep your plant running like a well-oiled machine!

Introduction

When it comes to planting maintenance, there are a few key things to keep in mind in order to prevent costly repairs down the line. First and foremost, effective plant maintenance requires regular check-ups and cleanings. This means that you should schedule time each week to inspect your equipment and ensure that it is free of debris and dirt. Additionally, you should create a preventive maintenance plan that outlines specific tasks that need to be completed on a regular basis in order to keep your equipment running smoothly.

Another important aspect of effective plant maintenance is identifying problems early on and addressing them before they become major issues. This means being vigilant about monitoring your equipment for any signs of wear or damage. If you notice anything out of the ordinary, don’t hesitate to reach out to a professional for help. Catching problems early on will save you both time and money in the long run.

Finally, remember that plant maintenance is an ongoing process – not something that you can set and forget about. By staying proactive and attentive, you can keep your equipment running efficiently for years to come.

What is Plant Maintenance?

Plant maintenance is the care and upkeep of machines and equipment in a factory, office, or another workplace. It includes routine cleaning, lubrication, and inspection, as well as more major repairs.

Plant maintenance is important for several reasons. First, it helps to keep machinery and equipment running smoothly and efficiently. Second, it can help to prevent costly repairs by catching problems early on. Finally, plant maintenance can improve worker safety by ensuring that machinery is properly maintained and functioning properly.

There are a few key things to keep in mind when it comes to planting maintenance. First, be sure to develop a regular cleaning and inspection schedule. Second, make sure that you have the proper tools and supplies on hand for routine maintenance tasks. Finally, be sure to keep an eye out for any potential problems so that you can address them before they become serious issues.

7 Effective Ways to Improve Plant Maintenance

Plant maintenance is a necessary evil. It’s often seen as a cost center rather than a profit center, and it’s easy to let things slide when money is tight. But effective plant maintenance can save you money in the long run by preventing costly repairs and downtime. Here are some ways to improve your plant maintenance program:

- Create a comprehensive maintenance plan.

Your plan should include regular inspections and preventive maintenance tasks for all of your equipment. By being proactive, you can identify potential problems before they cause major damage.

- Implement a preventive maintenance program.

Preventive maintenance tasks are designed to keep equipment running smoothly and prevent expensive repairs down the road. These tasks may include things like oil changes, filter replacements, and lubrication.

- Keep accurate records.

Good recordkeeping is essential for effective plant maintenance. Keep track of all work that’s been done on each piece of equipment, including the date, time, and who performed the work. This information will be invaluable if something goes wrong later on.

- Train your employees properly.

Your employees need to know how to properly operate and maintain your equipment. Make sure they understand your maintenance procedures and have the skills needed to carry out those procedures safely and effectively.

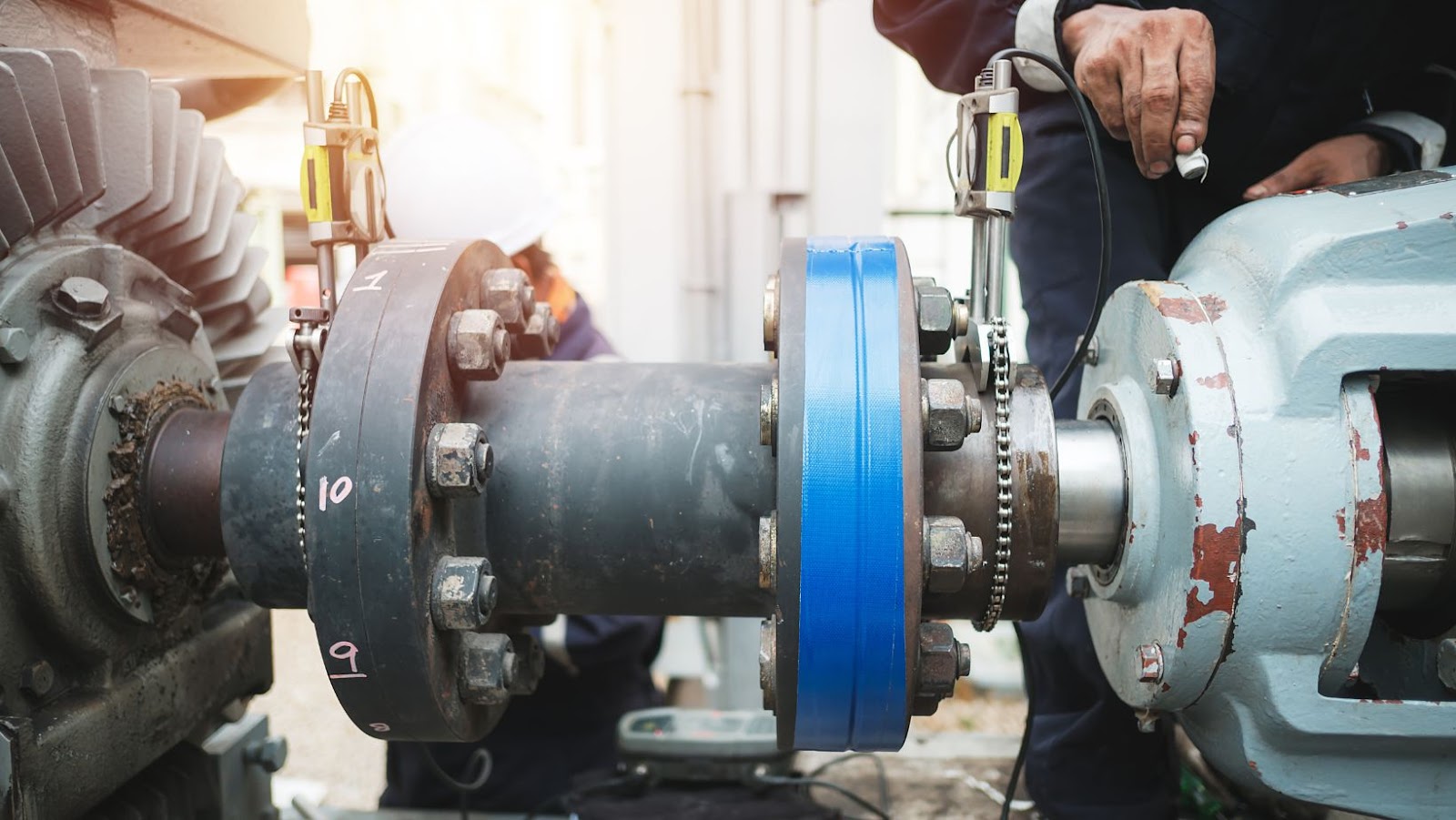

Regularly Inspect Equipment and Systems

It is important to regularly inspect all equipment and systems in a plant in order to identify potential problems before they become serious. This can be done by trained personnel or by using specialized inspection equipment.

If problems are found, they should be fixed immediately. This will help to prevent more expensive repairs from being needed later on.

Regular inspections will also help to identify wear and tear on equipment so that it can be replaced or repaired before it fails completely. This will minimize downtime and keep the plant running smoothly.

Implement a Preventive Maintenance Schedule

It is important to implement a preventive maintenance schedule in order to avoid costly repairs and improve plant maintenance. A preventive maintenance schedule includes regular inspections, checks, and servicing of equipment and machinery. This helps to identify potential problems early on and take corrective action before it leads to a breakdown.

Some tips on implementing a preventive maintenance schedule:

- Inspections should be conducted on a regular basis, at least once a month.

- Checks should be carried out on all critical parts of the machinery or equipment.

- Servicing should be done according to the manufacturer’s specifications.

- Documentation of all inspection, check, and servicing activities must be kept for future reference.

Utilize Automation Tools

- Utilize Automation Tools

The first step in improving plant maintenance is to utilize automation tools. These tools can help you keep track of equipment performance, schedule maintenance tasks, and predict when repairs may be needed. By automating your maintenance processes, you can improve efficiency and prevent costly downtime.

- Implement Predictive Maintenance

Predictive maintenance is a proactive approach to plant maintenance that uses data analytics to identify potential problems before they occur. By implementing predictive maintenance, you can fix issues before they cause extensive damage or downtime. This approach can save you time and money in the long run.

- Use Condition-Based Monitoring

Condition-based monitoring is another proactive approach to plant maintenance that uses sensors to monitor the condition of the equipment. This data is then used to predict when repairs or replacements may be needed. By using condition-based monitoring, you can avoid expensive downtime and keep your equipment running smoothly.

- Perform Regular Maintenance Checks

Regular maintenance checks are essential for preventing expensive repairs down the line. By regularly inspecting your equipment, you can identify small issues before they become big problems. This regular upkeep will save you time and money in the long run.

Train Employees on the Proper Use of Machinery

Most manufacturing plants rely on a variety of machines to produce their products. While these machines are essential to the production process, they can also be dangerous if not used properly. That’s why it’s important to train your employees on the proper use of machinery before they begin working in your plant.

There are a few things you should cover during employee training on machinery use:

- The dangers of operating machinery without proper training or supervision

- The importance of following all safety procedures when using machinery

- How to properly operate each type of machine in your plant

- What to do if something goes wrong while operating a machine

By covering these topics, you can help ensure that your employees know how to safely and effectively use the machinery in your plant. This will help reduce the risk of accidents and costly repairs and ultimately help keep your production line running smoothly.

Monitor Inventory Levels

It is important to monitor inventory levels in order to ensure that items are available when needed and to avoid costly repairs. The following tips can help you keep track of inventory:

- Keep a running list of inventory items and their quantities on hand. This will help you quickly identify when items are running low.

- Use an automated system to track inventory levels. This can save time and help to ensure accuracy.

- Schedule regular physical checks of inventory levels. This will help you catch any discrepancies between the actual quantity on hand and what is reported in the system.

Utilize Safety Procedures and Practices

There are a number of safety procedures and practices that should be followed in order to improve plant maintenance and prevent costly repairs. These include:

- Always follow the manufacturer’s safety instructions when using any type of machinery or equipment.

- Make sure all workers are properly trained in the use of any safety equipment that is required for their job.

- Inspect all machinery and equipment regularly to ensure that it is in good working order.

- Report any problems with machinery or equipment immediately to a supervisor.

- Never try to repair machinery or equipment yourself unless you are properly trained to do so.

- Follow all safety procedures when handling hazardous materials.

- Always wear the proper personal protective equipment when working in areas where there is a potential for exposure to hazards.

Invest in Quality Products and Materials

When it comes to plant maintenance, one of the most effective ways to prevent costly repairs is to invest in quality products and materials. This means using high-quality equipment and tools that are designed to last, as well as investing in proper training for your staff.

By investing in quality products and materials, you can be sure that your plant will be able to run smoothly and efficiently for years to come. Additionally, you will be less likely to experience unexpected downtime or have to deal with costly repairs.

Conclusion

Plant maintenance can be a challenging but rewarding task. Taking the time to properly maintain your plant equipment and prevent costly repairs is essential for any business. We hope that our seven tips have given you some ideas on how to effectively improve your plant maintenance practices and save yourself some money in the long run. Now get out there, start implementing these techniques, and keep your plants running smoothly!

What's Your Reaction?

Deepak is a lover of nature and all things sporty. He loves to spend time outdoors, surrounded by the beauty of the natural world. Whether he's hiking, biking, or camping, Deepak enjoys being active and in touch with nature. He also loves to compete and push himself to his limits. Deepak is an avid cyclist, runner, and swimmer. He has competed in several triathlons and marathons, and is always looking for new challenges to take on.